Xilinx FPGA based Tea Color Grading System

This system is proposed for the final stages of tea processing for the low grown tea industry as a import substitution. Once completed the system is to be demonstrated to tea factories for possible client applications. Currently, the phase two of the system is completed with actual tea sample color separation testing. This system incorporates the mechanical system including bucket loader system, vibrators (evenly distribute tea particles), guides, collecting bins, and particle ejecting mechanisms. This system has a Xilinx FPGA for high speed image processing (camera based).

The machine operates on the principle of identifying different types of tea particles based on color and separating them by activating a pneumatic actuator system. The system captures images of moving tea particles through a Charged Coupled Device (CCD) high-speed camera and processes that image data using Field Programmable Gate Array (FPGA) and advanced electronic systems.

- Tea grading according to color in low-grown area tea estates/factories.

- This is very much necessary for factories producing tea for auctions in the international market, whose concern is mostly on the appearance of the tea samples.

- For factories concerned with low investment for this kind of machine rather than imported ones (Imported price Rs. 10M – 20M).

- High-resolution CCD camera for color detection

- High-speed FPGA based electronics for processing

- Mechanical system with high-speed valves and stainless-steel channels

Floodgate Automation at the Department of Irrigation, Matara (2018-2019)

Introduction

There are 13 pump houses under Gin and Nilwala river flood protection schemes. Basic concept of the schemes is the protection of lower basin from river flooding by pump houses evacuating excess water from the protected area (Yaya side) to river side. Pumping and gravity draining is used to evacuate the excess water in protected area depending on river and protected side water level. However pumping is a high costly process in operation and maintenance. Gravity outlet operation is very important to cut down the above cost of pump running. It is well known that more than Rs. 60 Million is spent annually for fuel and electricity.

At present all the pump houses are fixed with river and landside manual gauges to monitor the water level and to make decisions for pump operation. Since this is a manual and less reliable due to human intervention, gravity outlet operation is not efficient (even a one centimeter level gravity difference can save pumping costs).

Last few years it has faced more disputes due to less finance allocation from the government for these routine tasks. Paddy fields of famers and low land residential areas are severely damaged during the flood instances.

Through an automated and reliable, quick data providing solution to the action points can streamline the operation of gravity outlets. It will greatly reduce the cost of daily operation and farmer conflict for the Irrigation Department.

Methodology

To better manage river water, monitoring at real-time at three gravity outlets (Thalgahagoda, Magallagoda, Thudawa) is necessary. The technology solution involves electronics, communications and IT. The interested water level monitoring at River side and Protected side (Yaya side) are to be done using ultrasonic sensor modules and microprocessor based systems (Product 1 as detailed and powered through 230VAC and solar panel). This microprocessor based system is equipped with relevant optional accommodations to connect additional sensor modules (ex. sensing diesel tank level at pumping site) and energizing actuators (future automating pumps)

Collected water levels at real-time will be displayed on site and communicated via GPRS (or SMS) to a Web server installed with the specific Software (Product 2 as detailed). Water level information will be recorded (with date time stamps) in the database of the server to be accessed from remote terminals.

Irrigation Engineers or Managers who are authorized to the system can access data (real-time or past data) through a computer or laptop installed with the terminal software (Product 3).

The system main system units to be designed are the Site Controller (Product 1) with the ultrasonic sensor module interfaces and solar/battery controller, Web based database server software (Product 2) and the Terminal connection software (Product 3). Overall system is based on electronics, mobile communications and server based IT product.

Reservoir and overhead tank water level display, logging and remote monitoring system at National Water Supply and Drainage Board (2013)

The water levels are sensed using IP67 standard outdoor type ultrasonic sensors in underground reservoirs and overhead tanks. In a site the sensor network carries level data to the central processing system and the information is locally displayed in LED displays and sent to a remote server and selected mobile phones at requested intervals. Real time and past data can be accessed from anywhere in IOT environment.

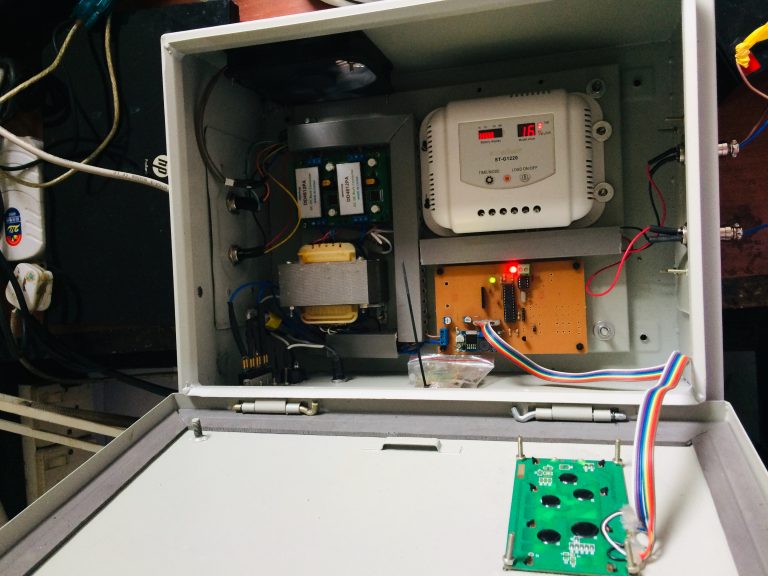

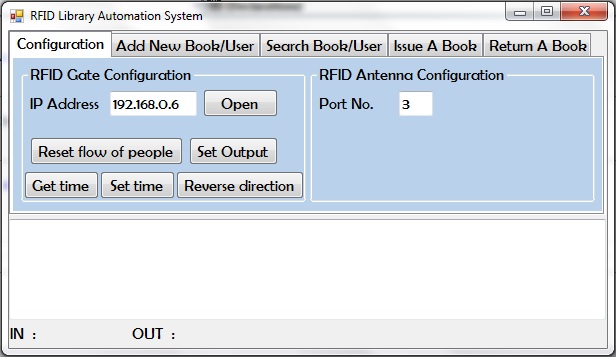

Library Function Automation

The library daily operations in book issuance, returning, database updating and the security functions are automated in this system. Every book is tagged using RFID sticker tags of anti-collision type and the library is having interrogator systems for the person identification (RFID Identity card) and the book identifications at the issuance desk. The system is automated and the database management and security functions (alarming on theft) are incorporated to the firmware system

GPS based Fleet tracking system

Tracking of vehicle movement is a much requested product (consists of hardware for vehicle installation to get GPS data and establish communication to the server, database and user software) for administrative and security purposes and to cope up with mishandling. The completed products were installed at the Sri Jayawardenapura hospital vehicle fleet and ACCIMT pool vehicles.

![dy[(001044)2019-05-24-10-13-25]](https://www.accimt.ac.lk/ACCIMT2/wp-content/uploads/2019/05/dy0010442019-05-24-10-13-25-1170x782.jpg)

![dy[(001964)2019-05-24-10-14-34]](https://www.accimt.ac.lk/ACCIMT2/wp-content/uploads/2019/05/dy0019642019-05-24-10-14-34-1170x782.jpg)

![dy[(002339)2019-05-24-10-14-45]](https://www.accimt.ac.lk/ACCIMT2/wp-content/uploads/2019/05/dy0023392019-05-24-10-14-45-1170x782.jpg)